At Sanden, the experimental and simulation departments work together to test and reconcile differences between simulation and experimental results, enabling the creation of more accurate model bases. This reduces the actual prototyping and reduces development costs and time for next-generation model design.

For example, experimental data on efficiency and pressure drops for each component of the cooling system is incorporated into simulations and compiled into a database to ensure consistent performance under a variety of conditions. This approach speeds up performance testing and further advances our development methodology.

Engineer’s Message

Integrated Thermal Management System (ITMS)The future of EVs and the global environment being opened up by ITMS

- Integrated Thermal Management System (ITMS)

-

- PAGE 01Further and More Comfortable, For Parts and People — EV Heat Management

- PAGE 02New Possibilities for Environmentally Friendly Refrigerants Opened up by ITMS

- PAGE 03Further Evolution of ITMS

- PAGE 04Roadmap to Becoming “World Number One”

- PAGE 05New Technology Initiatives and Sustainable Product Development

05New Technology Initiatives and Sustainable Product Development

- How do you conduct product development?

-

Okawara:

- How do you see ITMS technology progressing in the future?

-

Okawara:

Okawara:

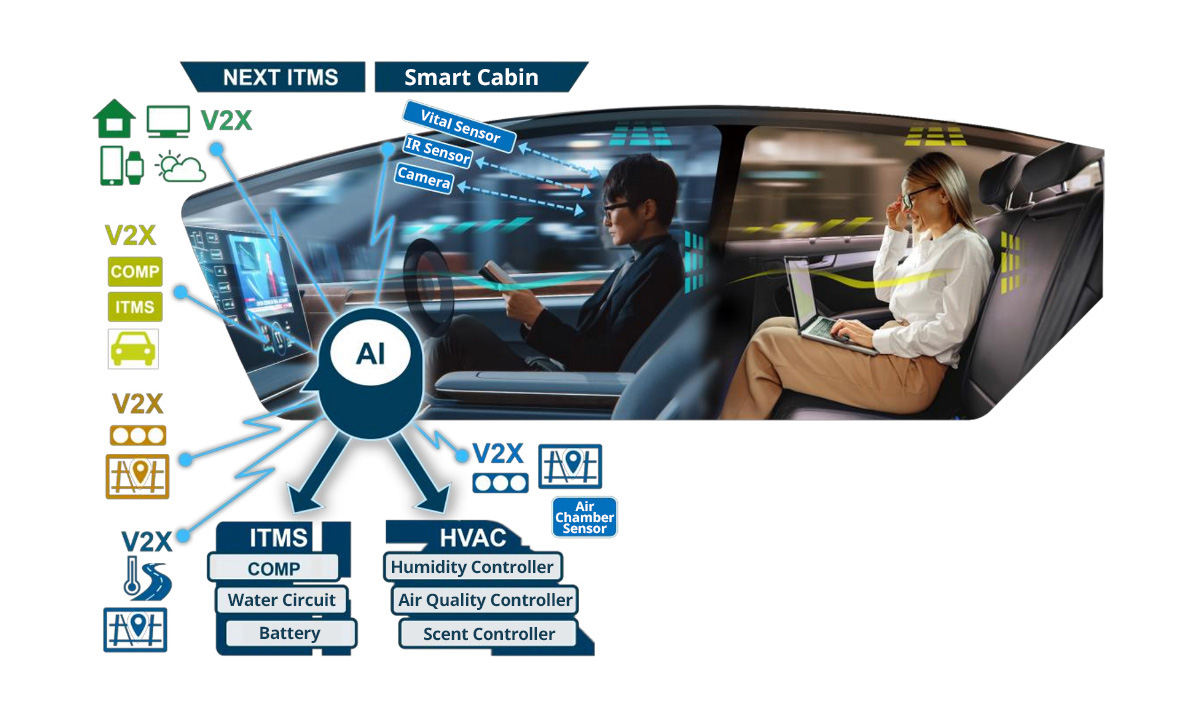

In the integrated thermal management system (ITMS), Sanden is taking vehicle comfort to a new level by introducing artificial intelligence (AI) technology, drawing on not only its own technologies, but also joint research with universities.

This is called “NEXT ITMS,” in which AI learns the preferences and behavioral patterns of drivers and passengers, and optimizes temperature and humidity management accordingly. This technology forms the core of our efforts to provide “ultimate comfort” in the vehicles of the future.

In terms of specific examples, the technology could learn patterns of household appliance usage with respect to the times when people use a vehicle, then automatically adjust the temperature and sterilize the interior before they get in. Another possible application might be technology that analyzes traffic signals and traffic conditions to optimize battery cooling and improve power efficiency. Other technologies we believe could be put to practical use include AI that senses occupant preferences and automatically sets the preferred cabin environment, and efficient control based on accumulated ITMS data to reduce electricity costs.

By combining Sanden’s ITMS technology with AI, we aim to create a personalized and comfortable cabin environment unlike any seen before, providing a sustainable and pleasant travel experience.

- What sort of contribution will ITMS make in terms of a sustainable global environment?

-

Okawara:

We believe that ITMS is an important technology that can contribute to the prevention of global warming because it improves the energy efficiency of the vehicle as a whole. Conventional refrigerants have a high global warming coefficient, and there are also concerns about the adverse effects of fluorine compounds on the human body and the environment. In response, manufacturers are developing new refrigerants with lower global warming coefficients, and Sanden is also pursuing technological innovations to reduce the environmental impact of refrigerants. Ultimately, we aim to build a society oriented toward resource recycling.

- Will Sanden’s technological development continue to evolve?

-

Okawara:

At the heart of Sanden’s product development is a strong desire to help solve social issues. By using ITMS to improve the energy efficiency of vehicles, we will reduce the load on power plants and optimize energy consumption, while at the same time contributing to measures to combat global warming.

In this way, Sanden, like automotive manufacturers, takes an approach based on how energy and materials are used, and maintains a commitment to sustainable product development.

Sanden’s technological development will continue to support sustainable development in the automotive industry by promoting environmentally friendly technological innovation and contributing to solving social issues.

- Thank you very much for your time.

-

The Future of ITMS

The Future of ITMS

- Home

- Product & Technology Information

- Technology Information

- Engineer’s Message page05