Environment

Efforts to Reduce Environmental Impact

Capital investment to reduce environmental impact

Sanden has been actively making capital investments to reduce environmental impact.

For blazing furnaces, which account for about 60% of plant facility costs, we have begun to introduce a new production system developed through the collaboration of industry, academia and government. The system is equipped with the world’s first sensing technology to visualize the temperature of products and AI-based functions to control the temperature of individual products, enabling us to expect that productivity will be increased by half and that electricity consumption will be reduced by 30%. We are currently working on the establishment of logic to collect teaching data for the shift to the new production system and introduction of AI.

Energy saving example

Yattajima Plant

Challenge to be addressed

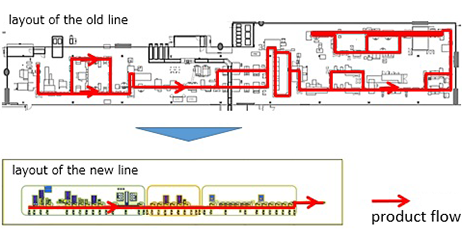

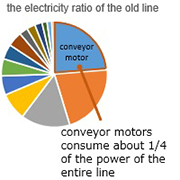

The conventional production lines, which use long belt conveyors, account for a large proportion of total electric consumption. To reduce the plant’s environmental impact, we considered the reduction of power consumption to be necessary.

Improvement

To make their length shorter, the plant’s belt conveyors were arranged linearly by promoting the compact modularization of production equipment. As a result, the belt conveyor length was reduced to 25% of that of the conventional system.

Effects

About 18% (Approx. 14kW) of total power consumption of production lines was reduced.