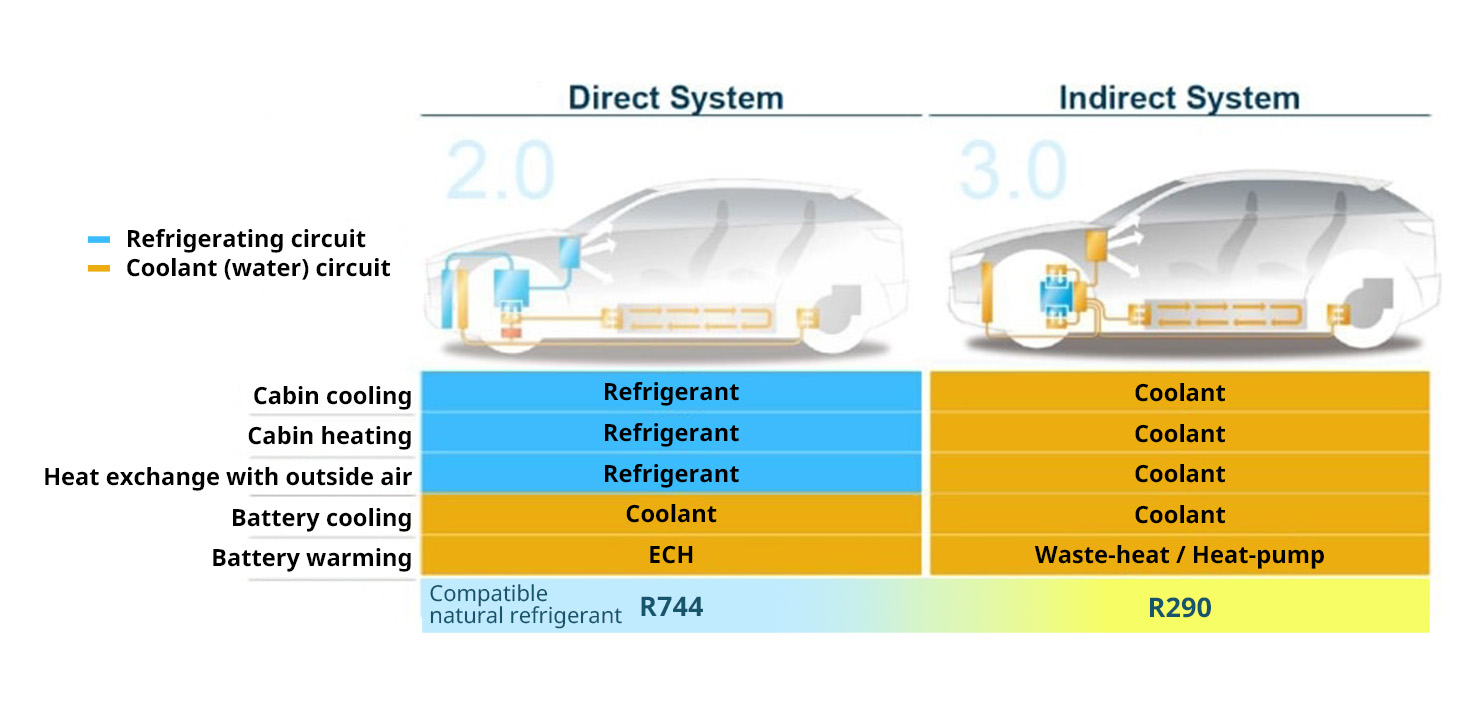

ITMS is a generic term for systems that recover and reuse exhaust heat from EV motors, batteries, and inverter systems. They use a heat pump mechanism to transfer heat by repeatedly compressing and expanding a refrigerant. When the temperature of the refrigerant is lower than that outside the vehicle, it absorbs heat, and when the temperature rises, it releases heat.

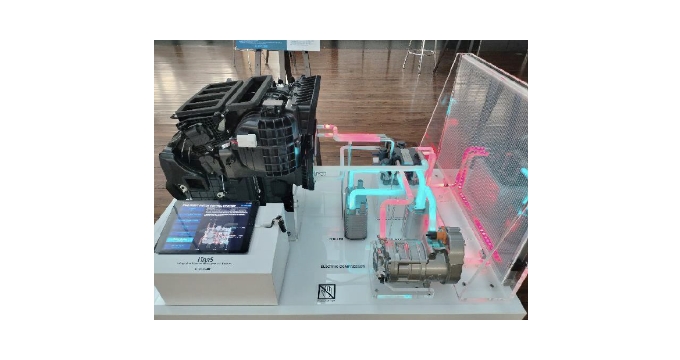

ITMS 2.0 incorporates an air conditioning unit (heat exchanger) containing refrigerant directly into the cabin (interior), where the refrigerant is used to provide cooling or heating.

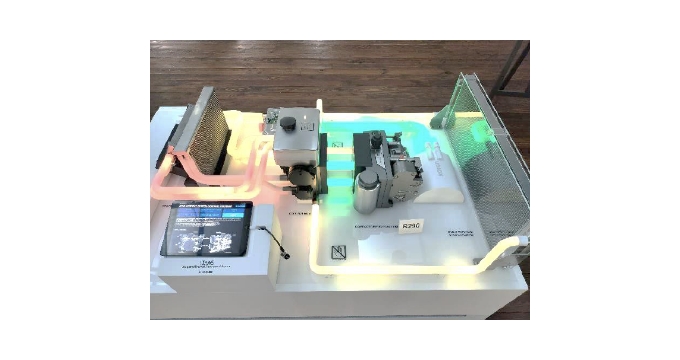

However, the refrigerant used in ITMS 3.0 is R290. The heat exchanger for the refrigerant is not located in the dashboard but is installed in-directly (indirectly) in the motor compartment, where water (coolant) cooled and heated by the refrigerant is carried to the heat exchanger to provide cooling and heating. This mechanism minimizes the risk of R290 refrigerant combusting or exploding in the cabin.

A key feature of Sanden’s ITMS 3.0 is that because the air conditioning unit is installed in the motor compartment, the main unit is very compact. Sanden has developed a Compact Refrigerant Unit (CRU) that has no refrigerant piping and is integrated into the main unit, reducing volume. Heat is transferred from the refrigerant to water in the CRU, and this water is circulated throughout the EV to control and manage the temperature of each component.

The reason for using water as the medium for transporting heat is to comply with PFAS refrigerant regulations, but it also serves to reduce the amount of R290 used. Even at the current stage, there is only a small amount of refrigerant used, but development is underway aimed at further reducing this amount.