Technology Information

With “cooling and heating” as its key technologies, Sanden aims to achieve a comfortable automotive environment.

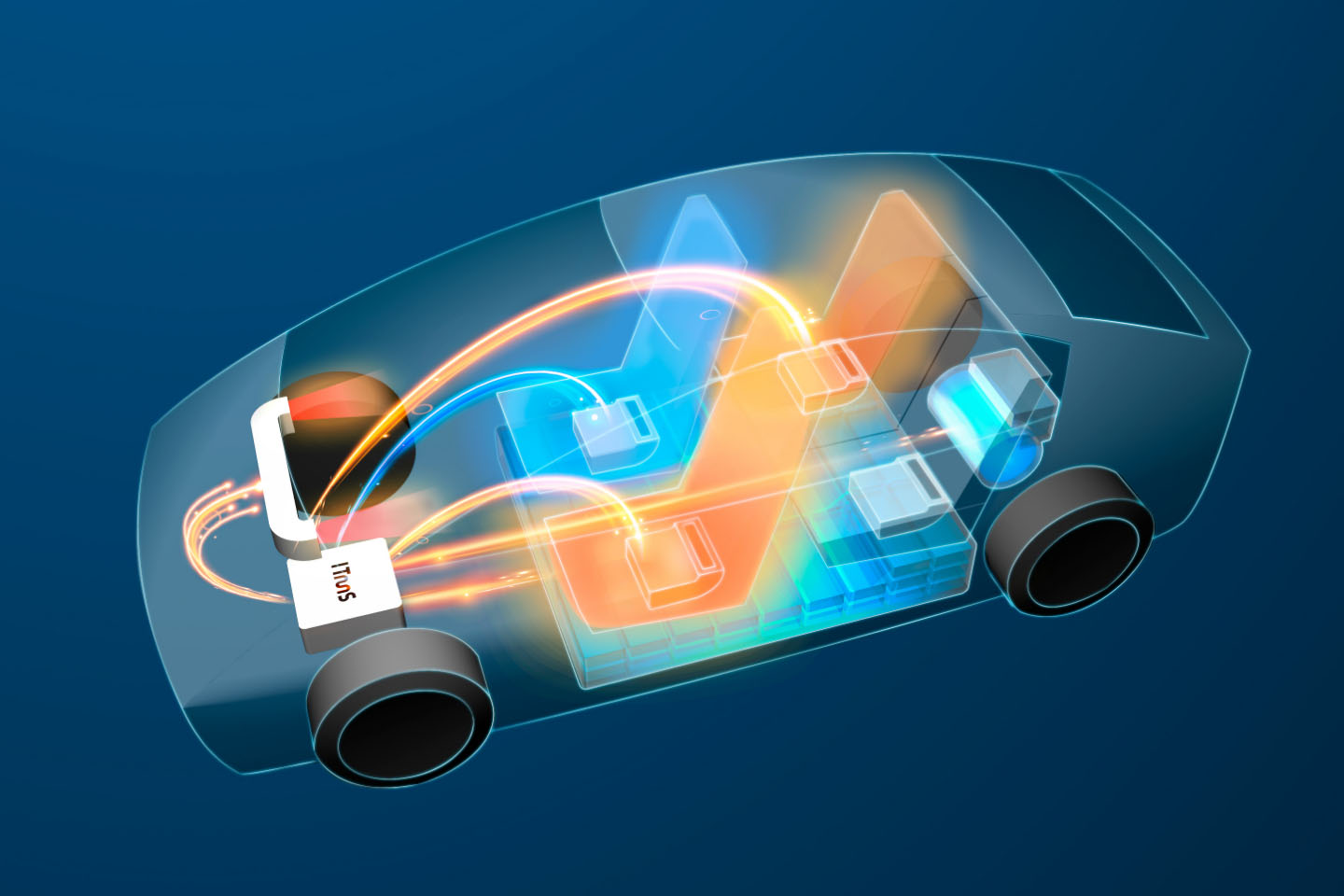

Using its core “cooling and heating” technologies, the Sanden Group has been engaged in the development and manufacture of compressors for automotive air conditioners and air conditioning systems. By drawing on our strengths in compressor technology, system technology, and heat pump technology, which we have cultivated over many years, we are developing efficient “integrated thermal management system” (ITMS).

We will continue to live up to the trust placed in us by major automotive manufacturers by applying our world-class technological capabilities to a variety of products, while contributing to the reduction of the global environmental burden through further fuel-saving and energy-saving technologies.

Integrated Thermal Management System

What are Integrated Thermal Management System (ITMS)?

Because electric vehicles (EVs) do not have engines, they cannot make use of the exhaust heat that engines produce. This means that turning the heating on increases the amount of power consumed by the drive battery, leading to a reduction in cruising distance. Sanden is developing integrated thermal management system (ITMS) that contribute to extended cruising distance and occupant comfort by effectively utilizing the thermal energy of EVs in an integrated manner.

- Recovering and effectively utilizing exhaust heat from EVs

-

Integrated thermal management system (ITMS) is an advanced technology developed specifically to improve the efficiency and performance of EVs. Sanden’s ITMS recover exhaust heat from powertrains such as motors and inverters and combines it with heat pump technology to effectively utilize thermal energy in EVs. An ITMS centrally manages the temperature of key vehicle components (such as batteries, motors, inverters, and in-car air conditioning) to support more comfortable and efficient driving.

- Reducing battery load, reducing loss of cruising distance

-

An ITMS reduces the load on the battery by maintaining the battery temperature at an appropriate level even in extremely hot or cold environments.

In addition, because it can efficiently provide a comfortable cabin environment, it helps reduce the load on the battery by suppressing excessive power consumption. This allows any loss of cruising distance to be minimized.

Sanden’s World-Leading ITMS Strategy

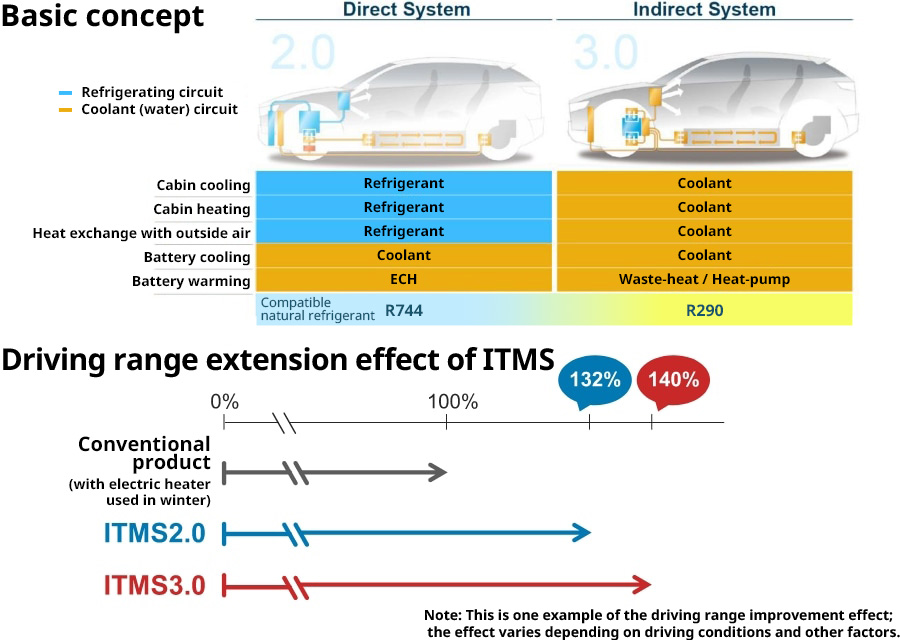

ITMS are being promoted in four key areas: high efficiency, comfort, modularization, and intelligence. Currently, we are rolling out ITMS 2.0 and ITMS 3.0, which use direct and indirect approaches respectively. We provide appropriate solutions tailored to each purpose and application, based on the size and specifications of the vehicle.

Our latest ITMS, 3.0, uses propane as a refrigerant to achieve environmentally friendly heat management. In addition, Sanden employs an “indirect system” to prevent refrigerant from entering the cabin directly. This also ensures the safety of the occupants. In addition, a compact refrigerant unit (CRU) has been adopted to significantly reduce refrigerant usage. This enables the system to be made smaller and lighter than conventional systems, reducing power consumption while delivering high thermal management performance.

- ITMS2.0

-

ITMS 2.0 uses the direct method, in which refrigerant is fed directly into the air conditioning unit. It has excellent responsiveness, enabling quick cooling and heating.

- ITMS3.0

-

ITMS 3.0 uses the indirect method, in which water is fed into the air conditioning unit via a water circuit. In systems that use propane gas as a refrigerant to comply with PFAS environmental regulations, the amount of refrigerant can be minimized.

- Basic Concept

-

Heat Pump System

What does Sanden’s heat pump system involve?

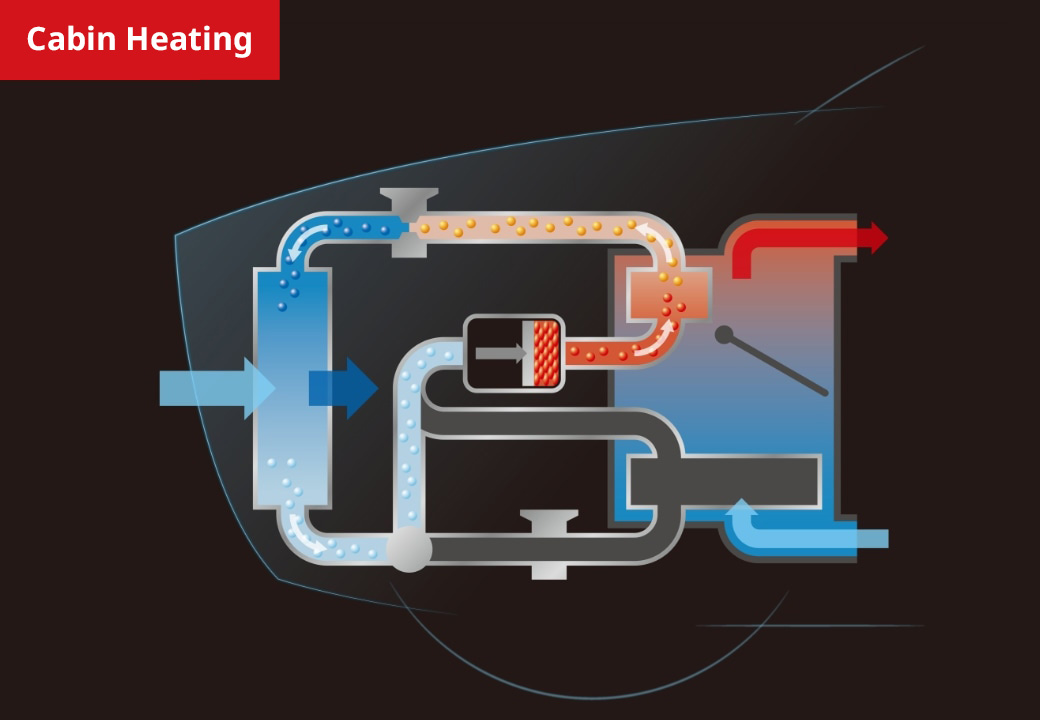

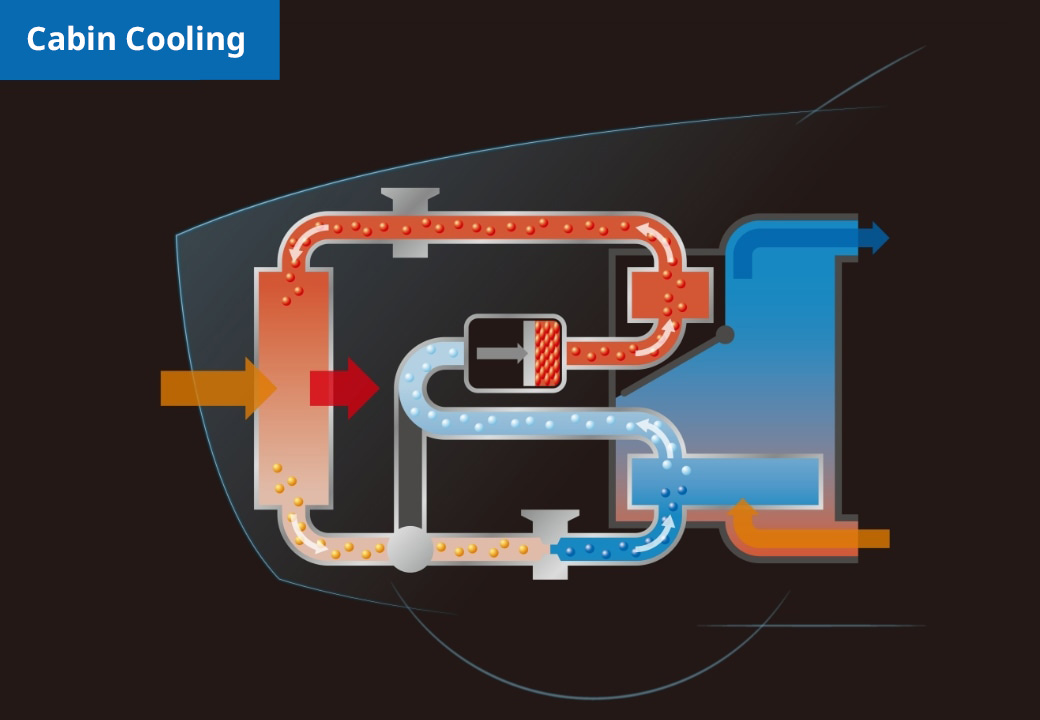

Heat pumps are air conditioning systems that use heat from the outside air and repeatedly compress, liquefy, and evaporate refrigerant to provide energy-efficient heating. Since EVs cannot use exhaust heat from the engine as a thermal source for heating, the development of energy-efficient heat pumps will allow for lower power consumption by the drive battery and keep any loss of EV cruising distance to a minimum.

Sanden began mass production of heat pump systems in 2017, and in 2018, the system was adopted in the Chinese electric vehicle market, a first for Chinese mass-produced vehicles (based on our own studies).

- Achieving a Comfortable Cabin Environment through Energy Savings

-

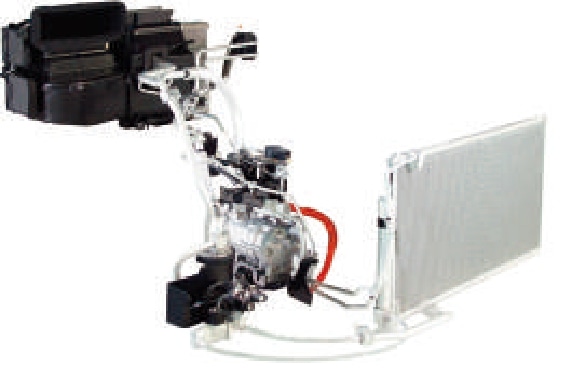

Our heat pump systems apply proprietary system configuration and control technologies that incorporate key components: electric compressors and heat exchangers. A new controller designed specifically for heat pumps has been developed to save energy and create a comfortable cabin environment.

- A Proprietary System Configuration Focused on Balancing Heating and Cooling

-

- An electric compressor that balances efficiency and reliability, taking into account heating operation at extremely low temperatures

- A vertical-flow outdoor heat exchanger that achieves a good balance between heating efficiency and drainage in heating and cooling

- A counter-flow indoor condenser that improves both heating efficiency and distribution of air discharge temperature

- A dedicated heat pump controller for optimal control of air conditioning and the refrigerant cycle

SANDEN COLUMNHow Heat Pump Systems Work

Heat pump systems are an energy-saving technology that efficiently utilizes thermal energy in the air for heating. These systems take advantage of the properties of refrigerants to generate more heat with less power.

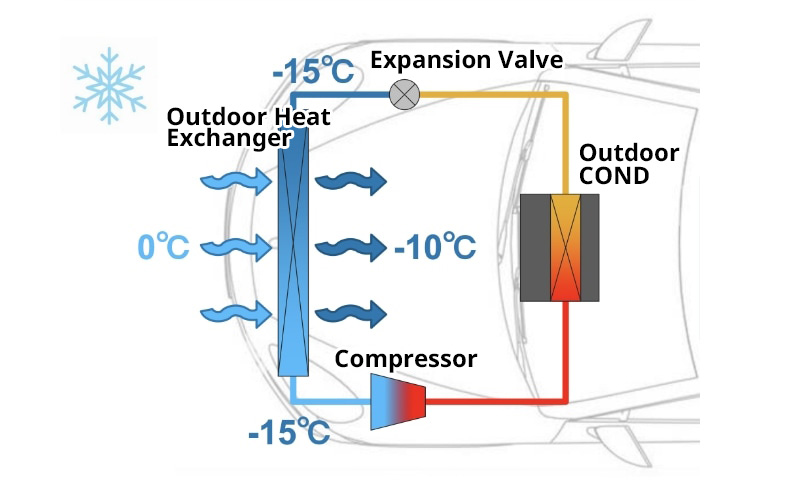

Refrigerants become hotter when they are compressed and cooler when they expand, and this property is harnessed to capture heat from the air.

- The Principle Behind Heat Pump Systems

-

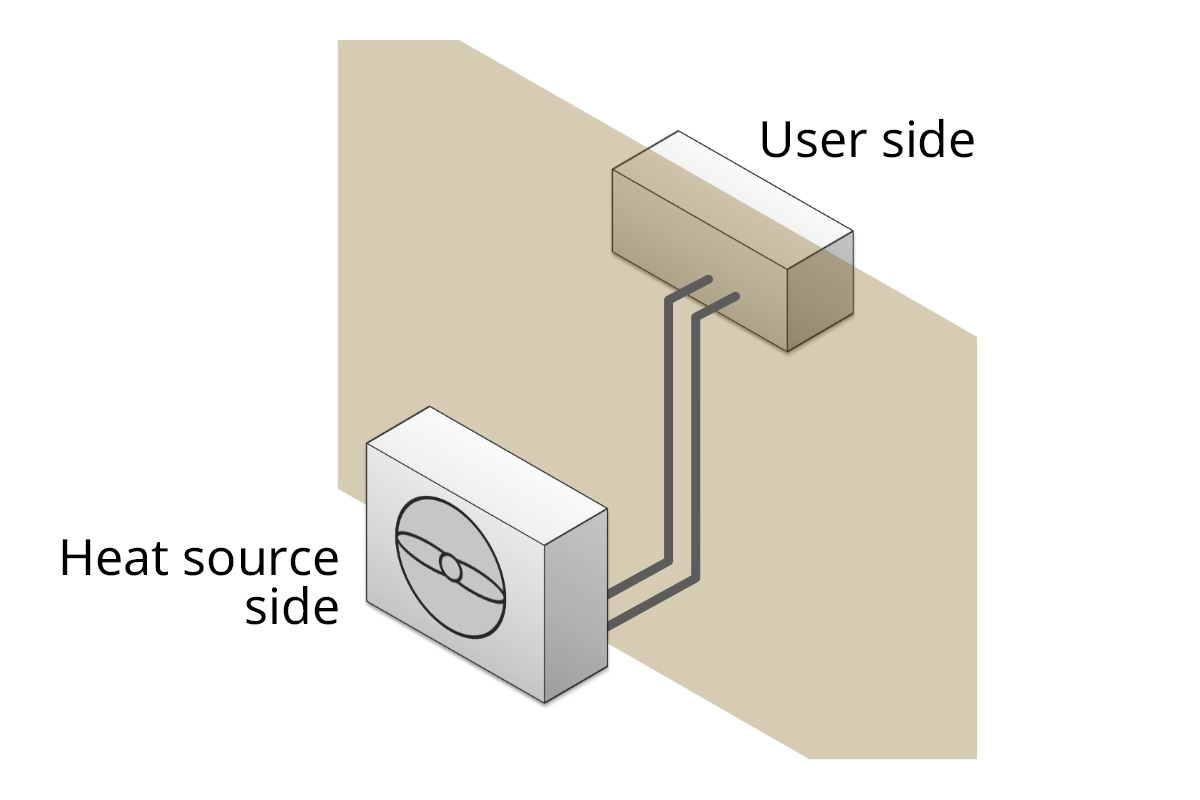

Heat pump systems consist of an outdoor heat exchanger that absorbs heat from the outside air, a compressor that compresses refrigerant to high temperature, and a condenser that releases heat from the high-temperature refrigerant into the room, all connected by pipes to circulate the refrigerant and supply heat energy to the room.

- Heat is transferred from the heat source to the refrigerant in the heat source-side heat exchanger

- Temperature raises in the compressor

- Heat from the refrigerant is used in the user-side heat exchanger

- The refrigerant is decompressed with an expansion valve to lower its temperature to a point at which it can absorb heat from the heat source

This mechanism means that if, for example, the heat source is air at 0°C, heat can be drawn even from this air by setting the refrigerant temperature to about minus 15°C.

In other words, it can provide effective heating in cold climates while reducing power consumption, minimizing battery drain in electric and hybrid vehicles and extending their cruising distance.